Translate this page into:

Evaluation of Different Techniques of Interproximal Reapproximation and Effectiveness of Finishing Procedures on Surface Nanotopography of Enamel - An Invitro Study

* Corresponding author: Dr. Chaitra C BDS MDS, Department of Orthodontics and Dentofacial Orthopedics, HKE Society’s S. Nijalingappa Institute of Dental Science, Gulbarga, India. chaitracshekar874@gmail.com

-

Received: ,

Accepted: ,

How to cite this article: C C, Patil BC. Evaluation of Different Techniques of Interproximal Reapproximation and Effectiveness of Finishing Procedures on Surface Nanotopography of Enamel - An Invitro Study. Dent J Indira Gandhi Int Med Sci. 2024;3:84-91. doi: 10.25259/DJIGIMS_6_2024

Abstract

Objectives

An in-vitro study was designed to evaluate different techniques of interproximal re-approximation and the effectiveness of finishing procedures on surface nanotopography of enamel. The aim of the study is to compare and evaluate the surface irregularities produced by interproximal reduction using Abrasive strips, Airotor burs, Mechanical and Chemical IPR techniques and the surface changes post-finishing procedure with polishing strips and the application of sealant on the reduced surface of the tooth.

Material and Methods

In this study, 50 proximal surfaces of 25 extracted premolars were considered which were divided into a control group (5 surfaces) and three experimental groups with 15 surfaces in each according to the stripping method employed (hand-held abrasive stripping using Ortho-Organizer strips, Airotor stripping using diamond bur HORICO company, number FG 166 010 and mechanical and chemical stripping using ortho organizer strip followed by 37% phosphoric acid gel) followed by finishing procedures by using polishing strips (3M Sof-Lex strips) and application of sealant (Helioseal F). All the reduced teeth samples were viewed under three-dimensional-3D non-contact optical profilometer and scanning electron microscope in Bengaluru, India.

Results

Air-rotor stripping generated more surface roughness (1.8 ± 0.14 μm) when compared with hand-held abrasive strip (0.96 ± 0.05 μm) and mechanical and chemical reduction (1.19 ± 0.11 μm) technique. Reduced tooth surface roughness in all groups after subjected to polishing, which had reduced surface roughness compared to unpolished surface. Further, application of sealant produced more smoother surface in all the groups.

Conclusion

Interproximal reduction technique carried out using abrasive strips generated less surface roughness compared to air-rotor stripping and mechanical and chemical stripping procedures. Finishing procedures on the reduced enamel surface produced the smoothest surfaces regardless of the technique and material used, making it necessary post-interproximal reduction. The combination that produced the least enamel surface roughness post-interproximal reduction in our present study was abrasive stripping using hand-held strips followed by sealant application.

Keywords

Interproximal reduction

Enamel

Surface roughness

Optical profilometer

Scanning electron microscope

INTRODUCTON

Interproximal re-approximation is otherwise called as interproximal enamel reduction, interdental stripping, enamel approximation or slenderization.[1]

The natural proximal abrasion of teeth was discussed by Black in 1902.[2] Later, numerous studies have been addressed on interproximal reduction. In 1944, Ballard[3] reported the interproximal reduction technique primitively. Sheridan[4] in labial technique, and Fillión[5] in lingual technique, among others, have contributed to the development of the interproximal reduction technique currently in practice. Begg’s[6] philosophy has shown that Australian aborigines did not have crowding which was ascribed to proximal wear of teeth surfaces. This has generated interest in clinicians to use proximal stripping in contemporary orthodontics. The paradigm shifts in treatment modalities in the present era, such as the importance of soft tissue profile and the upsurge for aesthetic appliances such as clear aligner therapy, has put forth proximal stripping as a viable treatment modality.

Interproximal enamel reduction is not carried out as a sole dental treatment but is most often combined with orthodontic fixed appliance therapy. Several renowned clinicians such as Hudson, Paskow, Peck and Peck, Sheridan, and Zachrisson have used proximal stripping to achieve ideal treatment results.

A common clinical procedure that has been expressed in the writings for decades is-

-

The most commonly used space-regaining procedure that aims at mesio-distal reduction of the tooth enamel surface, re-contouring the anatomic form of the tooth, and protection of prepared proximal surfaces of the tooth.[4]

Stripping[7–9] is a relevant remedial alternative for-

-

Borderline extraction cases.

-

Arch expansion.

-

Solving mild to moderate crowding up to 8–10 mm.

Orthodontists can effectively follow interproximal slicing in various aspects of clinical practice for-

-

The formation of black triangle seen due to interdental gingival recession by re-contouring the proximal surface and increasing the contact area between the teeth.

-

Stripping doesn’t alter the facial profile of the patient which might be seen in some cases of tooth extraction.

-

Reducing potential future relapse and overall treatment time.

However, this intensive procedure naturally reconstructs the tooth enamel, changing the surface morphology and contour of the tooth, which when not performed correctly creates an uneven surface on the proximal surface of the teeth which has a high risk of plaque retention and may lead to increased risk of gingivitis, periodontitis, dental caries and sensitivity.

Nevertheless, study research conducted in recent years has shown that if the procedure performed is carried out comprehensively, it will not induce iatrogenic dental caries or periodontal pathology.

Numerous techniques for proximal stripping and many companies produce a wide range of these abrasive strips, disks, and burs. The conduct of this study is to evaluate the enamel surface topography produced by three different stripping methods, the change in surface topography after the finishing procedure using polishing strips, and the change in surface topography after application sealants using 3D non-contact optical profilometer and scanning electron microscope (SEM).

Material And Methods

A total of 25 extracted premolars for the study were collected from orthodontic patients indicated with premolar extraction treatment plans for the purpose of fixed orthodontic mechanotherapy.

Inclusion criteria

-

Extracted teeth with intact enamel removed from patients undergoing orthodontic treatment.

-

Non-carious proximal surfaces.

-

Teeth with sufficient enamel thickness measured by radiographs.

Exclusion criteria

-

Abraded proximal surface.

-

Premolars with proximal caries.

-

Proximal surfaces with white spots and enamel cracks.

-

Teeth with proximal surface restorations.

-

Teeth with any developmental anomalies.

Methodology

-

The extracted teeth were cleansed with 3% hydrogen peroxide and normal saline and stored in 0.1% Thymol solution in a sealed container. At the time of conducting the research, the selected teeth were washed to remove the existing film and dried. The teeth samples were then mounted on orthodontic stone such that the roots were covered. This was done to assist the experimental procedure, that is proximal stripping and polishing. A digital radiovisiograph of each tooth sample was taken before reduction to calculate the enamel thickness. The mounted teeth samples were divided into four groups randomly and color-coded

-

Group I: Control Group—Yellow

Five sound non-treated surfaces.

-

Group 2: Hand-held proximal stripping was carried out on the proximal surfaces of teeth using a stripper handle. The teeth were reduced till 0.5mm on each side. Forty passages of 6 cm long abrasive strips and finishing strips were used. The teeth were reduced till 0.5 mm on each side.

-

a)

Subgroup UP (unpolished)—IPR showing hand-held proximal abrasive strips.

-

b)

Subgroup P (polished)—IPR showing hand-held proximal abrasive strips followed by polishing using polishing strip.

-

c)

Subgroup S (sealant application)—IPR using hand-held abrasive strips followed by application of sealant and curing the sealant using LED

-

-

Group 3: Air-rotor stripping was carried out using an air-rotor hand-piece as per the guidelines given by Sheridan. He recommended use of a high-speed air-rotor turbine hand-piece with a light, wiping stroke.

-

a)

Subgroup UP (unpolished)—IPR procedure using air-rotor bur.

-

b)

Subgroup P (polished)—IPR procedure using air-rotor burs followed by polishing using a polishing strip.

-

c)

Subgroup S (sealant application)-IPR procedure using air-rotor followed by application of sealant and curing the sealant using LED.

-

-

Group 4: Mechanical and chemical stripping (37% phosphoric acid)—the tooth samples were first subjected to mechanical reduction by IPR strips as standardized by Sheridan followed by the application of the phosphoric acid gel.

-

a)

Subgroup UP (unpolished)—IPR showing hand-held proximal abrasive strips followed by application of 37% phosphoric acid gel.

-

b)

Subgroup P (polished)—IPR showing hand-held proximal abrasive strips and 37% phosphoric acid gel followed by polishing using polishing strip.

-

c)

Subgroup S (sealant application)—IPR using hand-held abrasive strips and 37% phosphoric acid gel followed by application of sealant and curing the sealant using LED.

-

The mesiodistal width of each tooth was measured using a digital calliper and entered. Radiovisiographs of each tooth after reduction were taken using the same standardization as followed before. The proximal surfaces in each group were reduced according to the technique mentioned. The reduced samples were then sectioned horizontally at cementum enamel junction. The sectioned crowns were further cut longitudinally in labio-lingual direction using a diamond cutting bur. The sectioned samples were then mounted on acrylic such that the reduced surfaces face upwards and color-coded for easy identification and documentation. The prepared samples were then analyzed under optical profilometer and SEM.

RESULTS

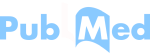

Table 1 and Graph 1 shows the distribution of surface roughness of the enamel surface roughness values of 10 groups calculated by optical profilometer. In the abrasive stripping group, mean surface roughness values were found to be 0.96 ± 0.05 μm in unpolished samples, 0.67 ± 0.49 μm in polished sample and 0.48 ± 0.044 μm in sealants. In air-rotor stripping group, mean surface roughness values were found to be 1.8 ± 0.14 μm in unpolished samples, 0.89 ± 0.02 μm in polished sample and 0.71 ± 0.04 μm in sealants. In chemical + mechanical stripping group, mean surface roughness values were found to be 1.19 ± 0.11 μm in unpolished samples, 0.75 ± 0.03 μm in polished sample,and 0.65 ± 0.03 μm in sealants. In the control group, the mean surface roughness values were found to be 0.59 ± 0.07 μm.

| Unpolished | Polished | Sealant | ||

| Abrasive Stripping-Orange | Mean (in μm) | .96100 | .67940 | .48840 |

| Std. Deviation | .052835 | .049652 | .044360 | |

| Minimum | .873 | .637 | .434 | |

| Maximum | 1.009 | .756 | .543 | |

| Airotor Stripping-Green | Mean (in μm) | 1.85840 | .89040 | .71940 |

| Std. Deviation | .149577 | .020768 | .049465 | |

| Minimum | 1.645 | .864 | .659 | |

| Maximum | 1.998 | .916 | .789 | |

| Chemical +Mechanical Stripping-Purple | Mean (in μm) | 1.19480 | .75200 | .65080 |

| Std. Deviation | .118946 | .033934 | .031475 | |

| Minimum | 1.059 | .712 | .613 | |

| Maximum | 1.345 | .798 | .692 | |

| Control Group -Yellow | Mean (in μm) | .59200 | .59200 | .59200 |

| Std. Deviation | .070498 | .070498 | .070498 | |

| Minimum | .510 | .510 | .510 | |

| Maximum | .680 | .680 | .680 | |

- Shows the distribution of surface roughness of the enamel surface roughness values of ten groups calculated by profilometer.

Analyzing scanning electron micrographs of proximal surfaces of enamel of extracted teeth of control group [group 1] and all experimental groups.

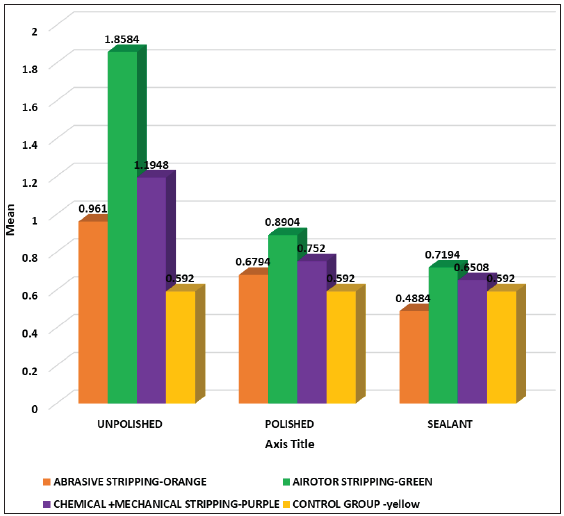

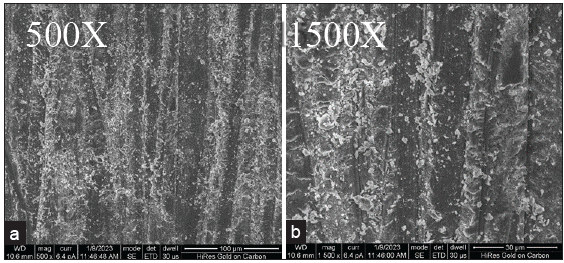

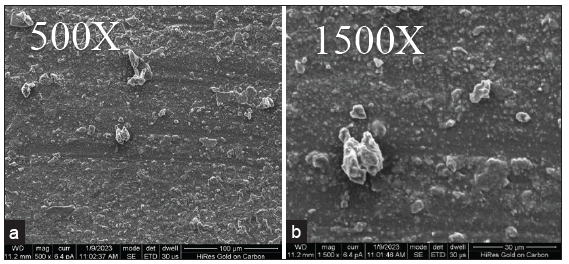

Group 1. Control Group

The proximal surface of the enamel in the control group was not completely even. Some minute troughs and irregularities were seen, which could be due to wear caused by tooth brushing or due to grinding of dietary food habits [Figure 1a and b].

- SEM images of surface appearance of control group under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope.

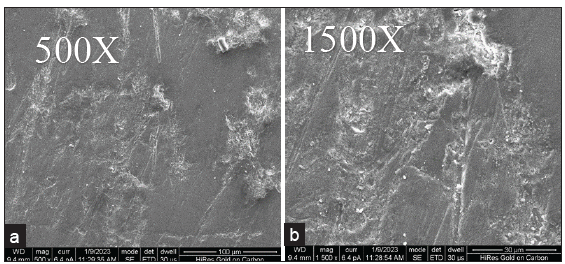

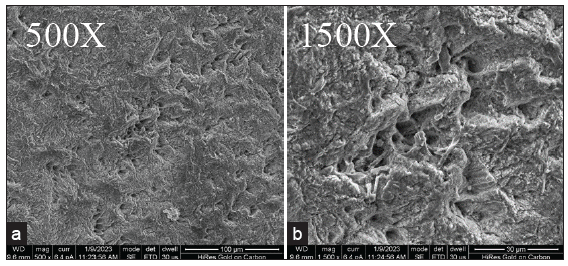

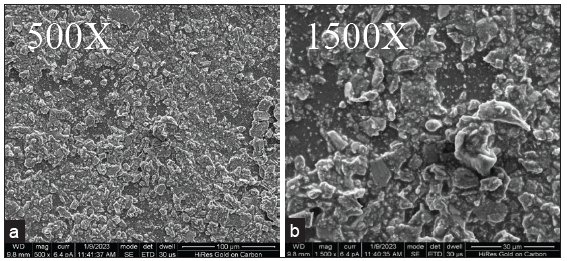

Group 2. Stripping by hand-pulled abrasive strips

The proximal surface of the enamel differed markedly from that of the control group. The surface appeared to be intertwined by deep and non-uniform indentations forming peaks and valleys, and no thin rod-like structure was evident in the enamel. The deep indentations were irregularly distributed and became clearly visible under both magnifications, 500x and 1500x [Figure 2a and b].

- SEM images of surface appearance subjected to IPR by hand held abrasive strips under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

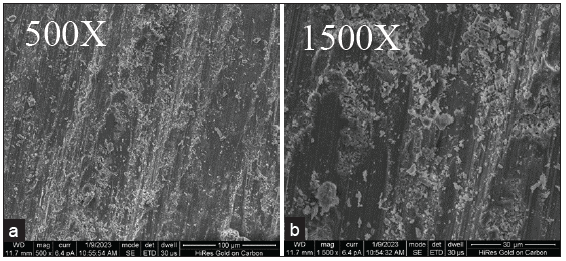

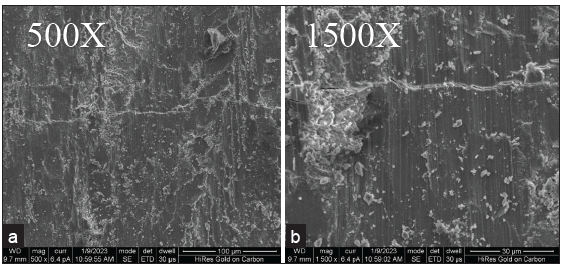

Group 3. Stripping by diamond burs

Surface topography of the enamel was markedly modified when subjected to interproximal reduction by diamond burs, troughs on the enamel surface appeared to be of greater depth and size. Stepladder-like depressions and deep circular depressions were seen at both 500x and 1500x magnification [Figure 3a and b].

- SEM images of surface appearance subjected to IPR by airotor stripping by diamond bur under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

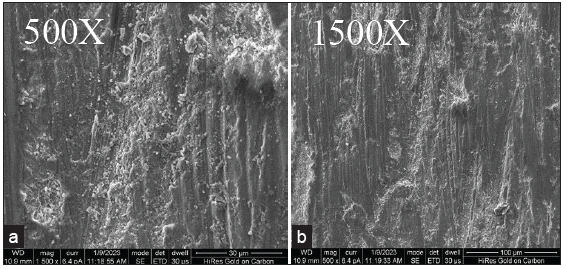

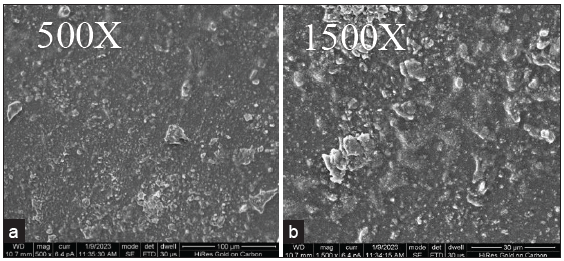

Group 4. Stripping by mechanical and chemical stripping

The topography of the enamel was significantly rough and resulted in severe destruction of the enamel surface, exposing enamel prisms and cores. Chemical stripping resulted in prominent scaling of the surface structure that can be susceptible to decalcification and accelerated plaque accumulation [Figure 4a and b].

- SEM images of surface appearance subjected to IPR by mechanical and chemical stripping under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

Group 5. Surfaces subjected to polishing strips post-reduction using abrasive stripping

The application of finishing strips reduced the sum total of troughs caused by abrasive strips and their depth of troughs. The troughs caused by stripping continued to be present on enamel surface, but were superficial and ring-shaped compared to unpolished surfaces. The surface obtained was susceptible to demineralization, but this risk was little compared to an unpolished surface obtained only by hand-drawn strips [Figure 5a and b].

- SEM images of surface appearance of polished samples after IPR using hand held proximal strips under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

Group 6. Surfaces subjected to polishing strips post-reduction using diamond burs

When the surface subjected to air-rotor burs was treated by polishing strips, it helped in reducing the troughs and indentation caused by the highly abrasive action of the drills. However, polishing with strips was not sufficient to ensure an adequate enamel surface. The enamel surface continued to appear rough with troughs and craters irregularly distributed over the entire reduced surface, although they were flat and smooth and were visible under both 500x and 1500x magnification [Figure 6a and b].

- SEM images of surface appearance of polished samples after IPR using Airotor stripping using diamond burs under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

Group 7. Surfaces subjected to polishing strips post-reduction using mechanical and chemical stripping

Finishing with polishing strips after IPR with the mechanical and chemical stripping was helpful in reducing the troughs and indentations caused by the highly abrasive action of the abrasive strips and phosphoric acid. However, polishing with strips was not sufficient to ensure an adequate enamel surface. The enamel surface continued to appear rough and irregular with troughs and cavities [Figure 7a and b].

- SEM images of surface appearance of polished samples after IPR using mechanical and chemical stripping under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

Group 8. Surfaces subjected to sealant application post reduction using abrasive strips

Sealant application post-reduction with hand-held abrasive strips showed that the effect of the sealer was restricted to filling in a few areas of the reduced enamel surface. The surface obtained appeared permeable and porous. The stripped surface appeared granular due to sealant clumps, but was smoother under both 500x and 1500x magnification compared to the surface obtained without sealing after reduction with hand-drawn abrasive strips [Figure 8a and b].

- SEM images of surface appearance of samples after IPR using abrasive stripping followed application of sealant under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

Group 9. Surfaces subjected to sealant application post-reduction using diamond burs

The application of a sealant after reduction with diamond burs proved beneficial in masking the profound troughs and stepladder appearance of the enamel surface that occurred during interproximal reduction of the enamel with diamond burs alone. A smooth enamel surface topography was obtained, with sealing clumps visible at both 500x and 1500x magnification [Figure 9a and b].

- SEM images of surface appearance of samples after IPR using airotor stripping followed application of sealant under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

Group 10. Surfaces subjected to sealant application post-reduction using mechanical and chemical stripping

Application of the sealer after reduction with mechanical and chemical stripping gave the reduced enamel a penetrable porous appearance. Sealer clumps were viewed at both 500x and 1500x magnification. The surface obtained was fine compared to the enamel surface treated with polishing strips [Figure 10a and b].

- SEM images of surface appearance of samples after IPR using mechanical and chemical stripping followed application of sealant under magnification (a) 500x and (b) 1500x. SEM: Scanning electron microscope, IPR: Interproximal reduction.

DISCUSSION

The SEM analysis revealed that the untreated enamel surfaces have a rough uneven appearance due to the presence of the perikymata with equal proportions of crests and troughs. The findings are compatible with the findings of Piacentini and Sfondrini.

Comparison of surface roughness of polished samples

Surface roughness created by abrasive strips was less compared to air-rotor stripping and mechanical and chemical stripping. The mean surface roughness produced by air-rotor stripping procedure was found to be 1.858 μm. This was 0.897 μm greater than the mean surface roughness produced by abrasive stripping, 0.233 μm greater than the mean surface produced by mechanical and chemical stripping. This was statistically significant, which was further supported by SEM evaluation of unpolished samples of all three groups resulted in roughened and grooved enamel surfaces at 500x and 1500x magnification, regardless of different techniques of interproximal reduction. When compared between abrasive stripping and air-rotor stripping, relatively less enamel was removed in abrasive stripping technique, whereas surface subjected to stripping burs resulted in more roughened surfaces, Moreover, enamel subjected to mechanical and chemical stripping shows that the combined mechanical and chemical treatment has to be clinically avoided for the orthophosphoric destructive action on the reduced enamel surface and makes enamel surface more porous and scalier which may increase plaque retention. Hence, our study shows that the abrasive stripping procedure is better than air-rotor stripping and mechanical and chemical stripping in terms of the surface roughness. This result allied with other studies proved that abrasive stripping procedures are better and safer compared to air-rotor reduction technique. Though air-rotor stripping is faster, it is recommended through our study to prefer mechanical reduction using abrasive strips, especially in the anterior teeth region where enamel thickness is less compared to posterior teeth.[7,8,9]

Comparison of surface roughness of polished samples

There was a statistically significant result seen when compared within groups.

The mean surface roughness produced by abrasive stripping polished was 0.679 μm, and there was 0.2816 μm reduction of surface roughness post-polishing with polishing strips. Similarly mean surface roughness produced by air-rotor stripping polished was 0.890 μm, there was 0.968 μm reduction of surface roughness post-polishing with polishing strips,and the mean surface roughness produced by mechanical and chemical stripping polished was 0.752 μm, there was 0.442 μm reduction of surface roughness post-polishing.

Surface roughness of enamel subjected to polishing after interproximal reduction resulted in a decrease in surface roughness in all the three groups subjected to polishing-by-polishing strips.

The significant decrease in surface roughness was appreciable in the image analysis obtained from SEM study—polished samples of all three groups resulted in relatively smoother surface compared to unpolished surfaces at 500x and 1500x magnification. The use of polishing strip after abrasive strips, stripping burs, and mechanical and chemical stripping seemed to produce additional traces and indentations on the enamel surfaces, yet resulted in comparatively smoother surfaces.

Comparison of surface roughness of IPR samples after application of sealant

There was a statistically significant result seen when compared within groups.

The mean surface roughness produced by abrasive stripping post-application of sealant was 0.488 μm, there was 0.473 μm reduction when compared to unpolished and 0.191 μm reduction of surface roughness compared to polished surface. Similarly, the mean surface roughness produced by air-rotor stripping post-application of sealant was 0.719 μm, there was 1.139 μm reduction when compared to unpolished and 0.171 μm reduction of surface roughness compared to the polished surface and mean surface roughness produced by mechanical and chemical stripping post-application of sealant was 0.6508 μm, there was 0.544 μm reduction when compared to unpolished and 0.102 μm reduction of surface roughness compared to the polished surface.

Surface roughness of enamel subjected to the application of a sealant after interproximal reduction resulted in decrease in surface roughness in all the three groups.

Correlating results were found with SEM, when samples were evaluated after the application of sealant in all three groups resulting in relatively smoother surface compared to unpolished and polished surfaces at 500x and 1500x magnification.

Overall, our findings demonstrate that, of the tested methods, stripping with metal strips followed by polishing and application of sealant produced the smoothest surface. Air-rotor stripping produced the highest roughest surface roughness which has to compulsorily undergo polishing to reduce the risk of caries and plaque accumulation.

Nonetheless, compared with the intact enamel surface, all experimental groups had significantly rougher surfaces with deep troughs and indentations. Thus, oral hygiene instructions, including plaque control and prophylactic measures such as topical fluoride application, must be given after interdental stripping to prevent undesirable sequelae of the procedure.

Limitations

The major limitation was the artificial set-up of the study.

In the oral cavity, the surface roughness produced by IPR will depend on various factors like saliva, blood, force applied by the clinician, duration, and contact points which were standardized during the study. Also, the direction of insertion of abrasive strips number of strokes of abrasive strips and burs will vary in the oral cavity.

Our major concern about the application of a sealant on the interproximal dental surfaces. In fact, the presence of saliva and the difficult access to the reduced interproximal surfaces of posterior teeth may interfere with the clinical application of sealants and the physiological wear and tear is an obstacle for their effective duration.

Scope for the study

Different techniques to apply sealant on proximal surfaces can be compared and evaluated.

Study can be conducted on large sample size.

Study can be conducted comparing various types of proximal strips, burs and discs that are commercially available.

In-vivo studies can be conducted on applying commercially available fluoride varnish to detect the amount of re-mineralization.

CONCLUSION

Within the experimental conditions and limitations of this study, the following conclusions were drawn:

-

Regarding quantitative evaluations, all experimental groups had indentations and troughs to a certain degree. Proximal enamel surfaces subjected to air-rotor stripping had deep craters and irregular surfaces compared to abrasive stripping. Chemical stripping resulted in prominent scaling of the surface, with the roughest and porous surfaces.

-

Despite producing additional traces and indentations, the use of polishing strips after abrasive stripping, air-rotor stripping, and mechanical and chemical stripping created smoother surfaces.

-

The smoothest and comparatively homogenous spread of sealant was found in samples subjected to sealant application post-abrasive stripping. Nevertheless, the application of a sealant on the proximal surface of the tooth has reduced accessibility.

-

With regard to surface roughness tests, quantitative measurements were consistent with SEM results and qualitative results.

From a clinical standpoint, polishing the stripped surface with polishing strips can significantly decrease the surface roughness of the reduced enamel surface.

Acknowledgments

I would like to express my special thanks to our mentor, Dr Basana Ouda C Patil, for the time and efforts he/she provided throughout this research project. Your useful advice and suggestions were really helpful to me during the project’s completion. In this aspect, I am eternally grateful to you. I would like to thank Dr Prathiba for helping me with statistical analysis.

Ethical approval

The study/research was approved by the Institutional Review Board, reference number HKES/SNIDSR/IEC/16/21 dated 22-02-2021.

Declaration of patient consent

The authors certify that they have obtained all appropriate patient consent.

Conflicts of interest

There are no conflicts of interest.

Financial support and sponsorship

Nil.

Use of artificial intelligence (AI)-assisted technology for manuscript preparation

The authors confirm that there was no use of artificial intelligence (AI)-assisted technology for assisting in the writing or editing of the manuscript and no images were manipulated using AI.

References

- Enamel reduction procedures in orthodontic treatment. J Can Dent Assoc. 2003;69(6):378-83.

- [PubMed] [Google Scholar]

- Descriptive anatomy of the human teeth (4th ed). Philadelphia: SS White Dental; 1902.

- Air-rotor stripping with the Essix anterior anchor. J Clin Orthod. 1996;30:371-373.

- [PubMed] [Google Scholar]

- Apport de la sculpture amélaire interproximale àl’ortodontie de l’adulte (troisième partie) Rev Orthop Dento Faciale. 1993;27:353-367.

- [Google Scholar]

- Begg orthodontic theory and technique. Philadelphia: WB Saunders; 1965. p. :74.

- Enamel thickness of the posterior dentition: its implications for nonextraction treatment. Angle Orthod. 1998;68:141-6.

- [CrossRef] [PubMed] [Google Scholar]

- Predictors of variation in mandibular incisor enamel thickness. JADA. 2007;138:809-15.

- [CrossRef] [PubMed] [Google Scholar]

- Current status of interproximal enamel reduction in orthodontic treatment. Pakistan Oral & Dental Journal. 2012;32:237.

- [Google Scholar]