Translate this page into:

"COATING STAINLESS STEEL AND NICKEL TITANIUM ARCH WIRES WITH ZNO NANOPARTICLES AND DETERMINING THE EFFECT ON FRICTION DURING SLIDING MECHANICS WITH METAL AND CERAMIC BRACKETS" - AN IN VITRO STUDY

Corresponding author : Dr. Shrutikirti Gupta Bhute

This article was originally published by Indira Gandhi Institute of Medical Science and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Introduction and Objectives:

Sliding mechanics is commonly used in fixed mechanotherapy, so it is essential to understand the impact of friction between the brackets and wire so that the proper force can be applied. In this study effect of ZnO coating on friction was compared during sliding mechanics between coated and uncoated SS and NiTi arch wires using metal and ceramic brackets.

Material & Method:

Eighty 0.19"×0.25" SS and NiTi arch wires with and without ZnO coating were used with SS & ceramic brackets of 0.22 slot. In order to coat ZnO nanoparticles, wires were first stored in ultrasonic bath of ethanol at 30°C for 30 minutes & then transferred to a test tube containing ethanol solution with 0.1 gm ZnO nanoparticle and kept in a waterbath at 80°C for 10 minutes. The bracket-arch wire unit was submitted to mechanical test with an universal testing machine. Descriptive statistical information including mean and standard deviation was calculated by Mann Whitney & Kruskal Wallis Test.

Results:

There was a significant difference (P value < 0.05 i.e. 0.011) of friction for coated and non coated arch wires, which was less for coated wires. There was significant difference among coated and uncoated wires (p value<0.05 i.e. 0.015 & 0.019) for SS & ceramic brackets, coated wires had less friction.

Conclusion:

ZnO coating has a positive effect on friction values during sliding mechanics which will enhance tooth movement by applying adequate force, decreasing friction & provide better anchorage control along with optimum biologic tissue response.

Keywords

Nanoparticles

friction

sliding mechanics

archwires.

INTRODUCTION:

Friction or resistance to sliding can be defined as resistance to motion when a solid object moves tangentially against another.1 In Orthodontics most of the fixed appliance techniques have some degree of sliding between bracket and arch wire. Whenever sliding occurs, frictional resistance is encountered, but the magnitude and clinical significance of this frictional resistance is largely unknown. The widespread adoption of preadjusted bracket system has increased interest in the use of sliding mechanics for the edgewise technique, in which friction may not be minimal. Therefore more information about the magnitude and clinical significance of frictional resistance is required.2

Orthodontic tooth movement results from the application of forces to the teeth. The Orthodontic appliances that are selected, inserted and activated by the clinician produce these forces. The teeth and their associated support structures respond to these forces with a complex biologic reaction that ultimately results in the teeth moving through their supporting bone.3

The ideal use of sliding mechanics would be to find the best combination of arch wire size, slot size, and force which would translate a tooth along an arch wire with minimal friction, without excessive tipping, and without unduly disturbing anchorage.4 Frictional resistance generated at the bracket arch wire interface is one of the important property that affects clinical performance. In the past few decades, a number of wire alloys with a wide spectrum of mechanical properties have been introduced adding versatility to Orthodontic treatment.5

To conquer friction in sliding mechanics, either higher force can be applied, which might lead to anchorage loss. Another alternative is to vary the wire size and shape, alter the bracket design or coating the wire surfaces with different materials which may aid in conquering sliding resistance.6 There have been variousmaterialsused for coating either brackets or wires. One of the method for conquering friction is the coating of wires with nanoparticles.

Nanotechnology is the the vital technology of 21st century. It has been used in the field of Orthodontics in various forms i.e. from surface coating to the development of new novel materials. British Standards Institution defines nanoparticles as those particles in which all the fields or diameters are in the nanoscale range. Nanoparticles are generally classified based on their dimensionality, morphology, composition, uniformity, and agglomeration. The various nanoparticles are nano pores, nanotubes, quantum dots, nano shells, dendrimers, liposomes, nano rods, fullerenes, nano spheres, nanowires, nano belts, nano rings and nano capsules.6

In order to reduce friction by surface coating with nanoparticles various composition of nano forms such as WS2, carbon nitride, ZnO, molybdenumdisulfide, diamond like carbon coating and nitrocarburizing and polysulfone embedded with hard alumina nanoparticles are available.

Maximum biological tissue response occurs only when the applied force is of sufficient magnitude to adequately overcome friction and it should lie within the optimum range of force necessary for movement of the teeth.7 Determining the approximate magnitude of friction in different clinical situation can assist in identifying the actual force employed in moving teeth.

This will help orthodontists to apply light forces to the peridontium while stimulating maximal biological force to the teeth being moved and minimal bone remodeling on anchorage tooth.

Therefore, it is essential to understand the impact of friction between the bracket and wire so that the proper force can be applied to obtain adequate dental movement and optimum biologic tissue response. The aim of the study was to evaluate the effect of ZnO nanoparticle coating on stainless steel and nickel titanium arch wires while sliding along metal and ceramic brackets of MBT prescription.

MATERIALS:

The materials used in the study were ZnO nanoparticle powder, ethanol solution, cold cure acrylic, Mathew's needle holder, cyanoacrylate glue, 0.010" stainless steel ligature wire, MBT prescription brackets of .022" x 0.28" slot stainless steel and ceramic brackets, 0.019" x 0.025" dimension rectangular NiTi& SS arch wires, Water bath, Universal testing machine and Scanning Electron Microscope. (Fig. 1)

- Materials used in the study

INCLUSION CRITERIA

0.019"x 0.025" arch wires, 0.022" slot MBT bracket, SS ligature wire, dry atmosphere at room temperature and ZnO nanoparticle in powder form and sliding mechanics.

EXCLUSION CRITERIA

Saliva, mouth temperature, other bracket system, other configuration and material of brackets and wire, other composition of nanoparticle and tubes, modules and auxillaries.

METHOD:

Coating of wires with ZnO

Stainless steel and NiTi arch wires were stored in ultrasonic bath of ethanol solution at 30°C for 30 minutes. This was done for the surface preparation of arch wires. In order to coat ZnO nano particles we had taken ethanol solution in a test tube and 0.1 gmZnO nanoparticle was added to the solution. The wires were then transferred to the test tube and kept in a waterbath at 80°C for 10 minutes.(Fig. 2)

- Waterbath used for heating

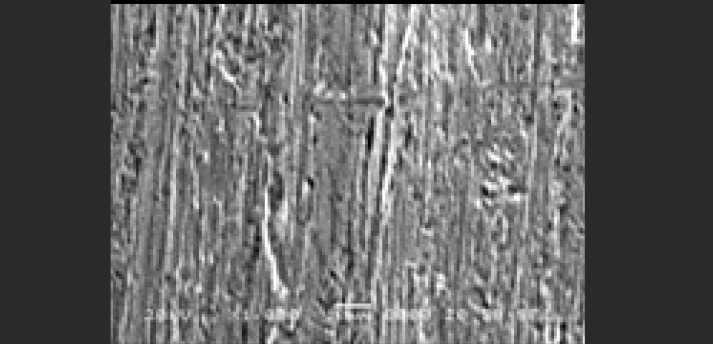

Both coated and uncoated arch wires of stainless steel and nickel titanium were viewed through SEM (Scanning Electron Microscope), in order to check the quality of coating. (figure 3, 4, 5 & 6)

- SEM image of uncoated NiTi

- SEM image of coated NiTi

- SEM image of uncoated SS

- SEM image of coated SS

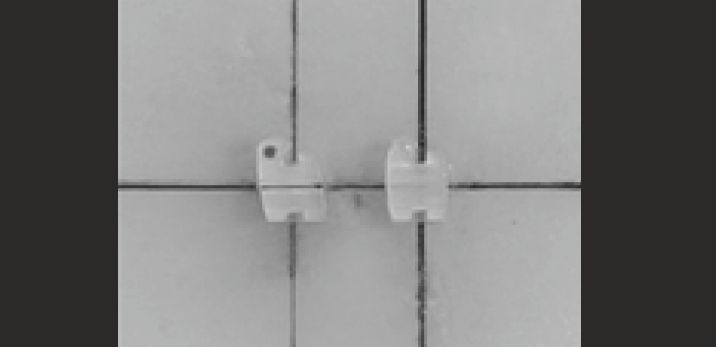

PREPERATION OF TESTING UNIT

Colored acrylic blocks were made of self cure acrylic and in order to differentiate the study into two groups two colors were used i.e. red and yellow. Red blocks were used to stabilize SS brackets and yellow brackets for ceramic brackets. Vertical and horizontal lines were drawn on the acrylic block in order to align the brackets uniformly. (Figure 7 & 8)

- Group A SS bracket

- Group B Ceramic bracket

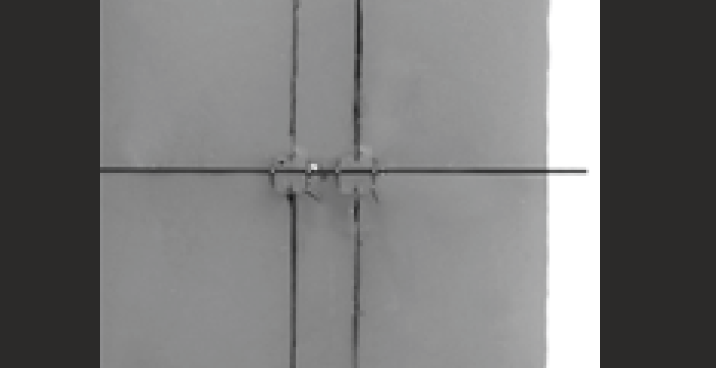

Once the brackets were in their proper position, we had placed the arch wires on the bracket slot and ligated them with 0.010 stainless steel ligature wire. (Fig.9a & b)

- Testing unit Group A

- Testing unit Of Group B

Evaluation of friction by universal testing machine

The frictional force of the testing unit, which consisted of the wire, bracket and ligation system was measured under dry conditions and at room temperature by using an Universal testing machine with load cell of 500 kg. (Fig. 10)

- Testing unit placed on universal testing machine

Each bracket slot was cleaned with spirit and dried with compressed air before running each test. The test wire was pulled through the brackets at a speed of 5 mm per minute. The drawing force was evaluated for each arch wire and bracket assembly on each occasion. The load cell registered the force level which was needed to move the wire along the two aligned brackets and the levels were transmitted to the computer.(Figure 10)

RESULTS:

The data obtained was subjected to statistical analysis with the consult of a statistician. The data so obtained was compiled systematically. A master table was prepared and the total data was subdivided and distributed meaningfully and presented as individual tables along with graphs. Statistical procedures were carried out in 2 steps:

Data compilation and presentation

Statistical analysis

Statistical analysis was done using Statistical Package of Social Science (SPSS Version 22; Chicago Inc., USA). Data comparison was done by applying specific statistical tests to find out the statistical significance of the comparisons. Quantitative variables were compared using mean values and qualitative variables using proportions. Significance level was fixed at P < 0.05.

Statistical tests employed for the obtained data in our study were:

Shapiro-Wilk test was applied to check the normalcy. The data obtaineddoesn't show the normality of distributionand homogeneity ofvariances assumptions required for parametric statistical tests. As the data showed skewed distribution, so non parametric test i.e. Mann Whitney 'U' Test was applied.

Mann Whitney 'U' Test Value was applied in order to find out the significant difference between two groups and Kruskal Wallis test was applied to find out significant difference among subgroups.

The Shapiro-Wilk test for determining then ormalicy of the data showed that the significance level was less than 0.05. The data was not normally distributed so we had used the non parametric test for the study (Table 1).

| Type of bracket | Statistic | Sig. |

|---|---|---|

| Stainless steel | .93 | .019 |

| ceramic | .94 | .044 |

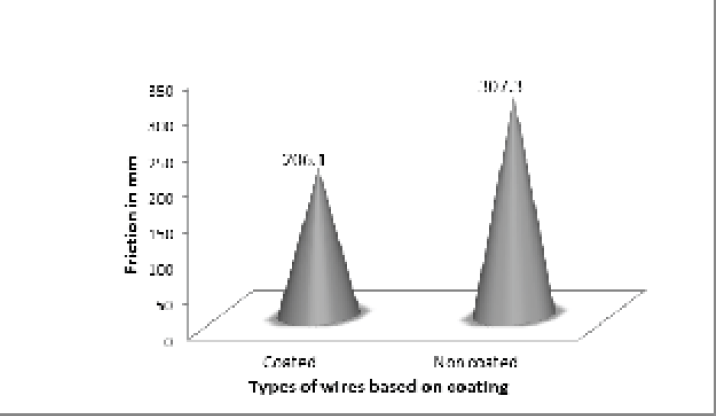

There was a significant difference in the friction values between bracket interface based on the coating of wire, by applying the Mann Whitney test. The p-value was < 0.011 i.e. significantly low values of friction were found in coated type of NiTi and SS archwires (Table 2 & Figure 11).

- Relationship between friction among groups based on the coating of wire

| Type of wire | N | Mean Rank | Mann-Whitney U | Significance |

|---|---|---|---|---|

| non coated | 40 | 47.08 | 537.000 | |

| Coated | 40 | 33.92 | .011 (S) |

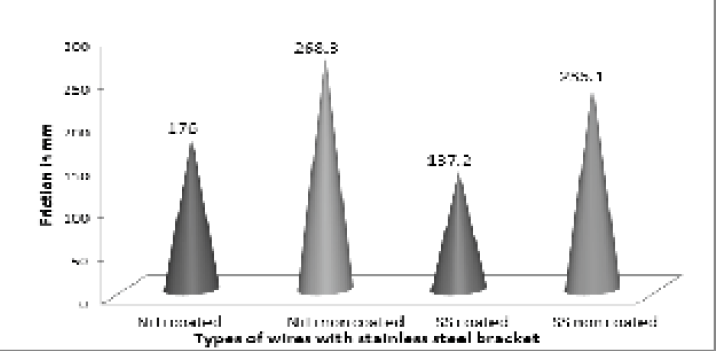

There was a significant difference in the values of friction between bracket interface based on the coated & non coated type of wire used with stainless steel type of bracket. The p- value was 0.00 which interprets highly significant value. There were low friction values for stainless steel coated type of wire. The friction values were significantly low for coated NiTi archwire also but it was more than the values obtained for stainless steel coated arch wires (Table 3 & Figure 12).

- Relationship between friction in stainless steel bracket group based on the type of wire used

| Type of wire | N | Mean Rank | Chi-Square | Significance |

|---|---|---|---|---|

| Stainless steel | 10 | 15.20 | 34.84 | .00 (HS) |

| NiTi | 10 | 34.50 | ||

| Stainless steelcoated | 10 | 5.80 | ||

| NiTi coated | 10 | 26.50 |

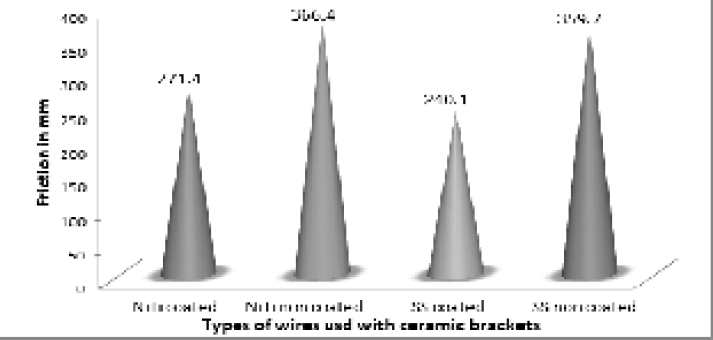

There was a significant difference in the friction values between bracket interface based on the coated & non coated type of wire used with ceramic brackets. The p- value was < 0.00i.e. highly significantvalue. The low values of friction were found in stainless steel and NiTicoated type of wire used. The value was least for stainless steel coated arch wires (Table 4&Figure 13).

- Relationship between friction in ceramic bracket group based on the type of wire used

| Type of wire | N | Mean Rank | Chi-Square | Significance |

|---|---|---|---|---|

| Stainless steel | 10 | 15.00 | 35.13 | .00 (HS) |

| NiTi | 10 | 34.95 | ||

| Stainless steelcoated | 10 | 6.00 | ||

| NiTicoated | 10 | 26.05 |

A significant difference between the friction between bracket interface in both type of bracket based on the coating of wire used. The p-value was < 0.05 i.e. significantly low values were found for coated type of wires for both stainless steel brackets and ceramic brackets and both stainless steel and NiTi arch wires. (Table 5)

| Type of Bracket | Type of wire | N | Mean Rank | Mann-Whitney U | Significance | |

|---|---|---|---|---|---|---|

| Stainless steel | Coated | 20 | 24.98 | 110.500 | .015 | |

| Non coated | 20 | 16.02 | ||||

| Ceramic | Coated | 20 | 24.85 | 113.000 | .019 | |

| Non coated | 20 | 16.15 |

DISCUSSION:

Nanoparticles are those particles in which all the fields or diameters are in the nanoscale range. It is an intentionally produced particle that has a characteristic dimension from 1 to 100 nm and has a properties that are not shared by non nano scale particles of same chemical composition. ZnO nanoparticles are available as powders and dispersions.8 These nanoparticles exhibit antibacterial, anticorrosive, antifungal and UV filtering properties. Some of the synonyms of zinc oxide nanoparticles are oxydatum, zincioxicum, permanent white, ketozinc and oxozinc.9 There was a significant decrease in friction for both NiTi and stainless steel arch wires when coated with ZnO nanoparticle.

Orthodontic archwires must have certain properties for example, high strength, low stiffness, high plasticity, excellent frictional properties, corrosion resistance, abrasion resistance, and biocompatibility so that they can be considered as effective oral device. In order to improve the overall performance of metallic materials many investigations and techniques have been carried out. Surface nanoengineering might enhance both the surface properties and performance of materials by changing surface organization and structure.10 In this study, we successfully deposited ZnO nanoparticles on the orthodontic stainless steel & NiTiarchwires. The ZnO films, provided excellent characteristics for friction compared with traditional archwires.

Prasad et al and Zabinskiet al concluded that decreased coefficient of friction after ZnO coating is related to their nanostructure properties which increase lubricating characteristics of the surfaces by participating in their plastic deformation and reducing friction in turn.11,12 Goto et aldemonstrated, using X- ray diffraction spectroscopy, that crystally preferred orientation of ZnO nanoparticles had a significant effect on their low frictional properties.13

Rapoport et aland Cizaire et al had explained the mechanism which reduces the friction after coating the wire and brackets with nanoparticle coating Nanoparticles reduce the friction by acting as a spacer initially when bracket and wire are parallel to each other and decrease the number of asperities in contact with each other andsome of these particles become flaked and the path of motion becomes slippery. Whereas in non coated wires and brackets amount of friction increases with increasing the angle between the wire and the slot.14,15

The condensed nanoparticles are slowly disintegrated under the application of force and undergo free failure at interfacial areas. Also in cases in which the two surfaces are stainless steel without nanoparticle coating, the friction coefficient increases, with further increases over time. It appears that such changes take place through oxidation and adhesion between the abraded surfaces. Therefore, deposition of ZnO nanoparticles decreases friction as a mechanism protecting wires against oxidation of metallic surfaces.16

The frictional values were found less by 25% in stainless steel arch wire and stainless steel bracket combination while it was 15% less in stainless steel arch wire and ceramic brackets combination. The frictional values were found less by 20% in NiTi arch wire and SS bracket combination while it was 10% less in NiTi and ceramic brackets combination.

Coated stainless steel arch wires had less friction values than coated NiTi arch wires which is due to surface characteristics of both the wires. Uncoated stainless steel had also less friction when compared to uncoated nickel titanium arch wires. Nishio et al, Garner et aland Dilip et al have studied frictional properties of different arch wires and concluded that stainless steel arch wires had less friction when compared to NiTi arch wires.17,18,19 There have been studies done by Redlich et al, Samorodnitzky et al and Behroozian et al with coating of nanoparticles like WS2, Carbon Nitride, Molybednum disulfide and Polysulfone embedded with hard alumina in which they have found significant reduction in friction along with improved corrosion resistance.20,21,22

The biggest advantages of ZnO nanoparticles are a low price, good gas sensing properties, photocatalytic activity, antibacterial activity, possibility to prepare structures with interesting optical properties and biocompatiblity. In small amounts ZnO is not toxic which have been studied by Nohavica et al and Bogutska et al. 3T3 tests have not shown any toxicity of ZnO on human cells. However, more meticulous studies are needed to determine the long-term effects on various tissues.23,24

CONCLUSION:

Nanoorthodontics is in its nascent stages of development. The merging of nanotechnology with orthodontics would help the clinicians in improving the quality of patient care and its application should be explored further. Zinc and its compounds can open wide possibilities of biomedical applications due to nanosize, optical, chemical, biological and pharmaceutical properties. ZnO nanoparticle coating significantly decreased the frictional force between brackets and wires for both the bracket and arch wire types.

Due to the positive effects of ZnO nanoparticle coating on decreasing frictional forces, these nanoparticles might offer a novel opportunity to significantly reduce friction during tooth movement and the consequent better anchorage control, reduced treatment time and risk of root resorption.

REFERENCES:

- The effect of Teflon coating on the resistance to sliding of orthodontic arch wires. European Journal of Orthodontics. 2012;34:410-417.

- [CrossRef] [PubMed] [Google Scholar]

- Frictional forces in fixed appliances. Am J Orthod Dentofac Orthop. 1989;96:249-54.

- [CrossRef] [PubMed] [Google Scholar]

- The role of friction in Orthodontics. Dental Press J Orthod. 2012;17(2):170-7.

- [CrossRef] [Google Scholar]

- A clinical evaluation of tooth movement along arch wires of two different sizes. Am J OrthodDentofacOrthop. 1983;83:453-59.

- [CrossRef] [PubMed] [Google Scholar]

- A comparative study of frictional resistances of stainless steel, nickel titanium, TMA, timolium and CAN arch wires with stainless steel brackets- an in vitro study. SRM University of Journal of Dental Sciences. 2010;1(1):63-67.

- [Google Scholar]

- Nanoparticles and their Applications in Orthodontics. Adv Dent & Oral Health. 2016;2(2) ADOH.MS.ID.555584

- [CrossRef] [Google Scholar]

- Mechanics of tooth movement. Am J OrthodDentofacOrthop. 1984;85(4):294-307.

- [CrossRef] [PubMed] [Google Scholar]

- Nanoorthodonticsrevolutionizingoral health care. Indian Journal of Oral Sciences. 2014;5(3)

- [CrossRef] [Google Scholar]

- Effects of nanostructured, diamondlike, carbon coating and nitrocarburizing on the frictional properties and biocompatibility of orthodontic stainless steel wires. Angle Orthod. 2016;86:782-788.

- [CrossRef] [PubMed] [Google Scholar]

- Tribiologicalbehavior of nanocrystalline zinc oxide films. Wear. 1997;203:498-506.

- [CrossRef] [Google Scholar]

- Lubrication using a microstructurally engineered oxide: Performance and mechanisms. TribolLett. 2000;8:103-16.

- [CrossRef] [Google Scholar]

- Low-friction coatings of zinc oxide synthesized by optimization of crystal preferred orientation. TribolLett. 2011;43:155-62.

- [CrossRef] [Google Scholar]

- Tribological properties of WS2 nanoparticles under mixed lubrication. Wear. 2003;255:785-93.

- [CrossRef] [Google Scholar]

- Mechanisms of ultra-low friction by hol-low inorganic fullerene-like MoS2 nanoparticles. Surf Coat Technol. 2002;160:282-7.

- [CrossRef] [Google Scholar]

- Fabrication of self-lubricating cobalt coatings on metal surfaces. Nanotech. 2007;18:115703.

- [CrossRef] [Google Scholar]

- In vitro evaluation of frictional forces between arch wires and ceramic brackets. Am J OrthodDentofacialOrthop. 2004;125:56-64.

- [CrossRef] [PubMed] [Google Scholar]

- A comparative study of frictional resistances of stainless steel, nickel titanium, TMA, timolium and CAN arch wires with stainless steel brackets- an in vitro study. SRM University of Journal of Dental Sciences. 2010;1(1):63-67.

- [Google Scholar]

- comparison of frictional forces during simulated canine retraction of a continous edgewise arch wire. Am J Orthod Dentofac Orthop. 1986;90:199-203.

- [CrossRef] [PubMed] [Google Scholar]

- Improved orthodontic stainless steel wires coated with inorganic fullerene-like nanoparticles of WS (2) impregnated in electroless nickel-phosphorous film. Dent Mater. 2008;24:1640-6.

- [CrossRef] [PubMed] [Google Scholar]

- Inorganic fullerene-like tungsten disulfidenanocoating for friction reduction of nickel-titanium alloys. Nanomedicine (Lond). 2009;4(8):943-950.

- [CrossRef] [PubMed] [Google Scholar]

- The effect of ZnO nanoparticle coating on the frictional resistance between orthodontic wires and ceramic brackets. . 2016;10(2):106-111.

- [CrossRef] [PubMed] [Google Scholar]

- Zinc and zinc nanoparticles: biological roleand application in biomedicine. UkrainicaBioorganicaActa. 2013;1:9-16.

- [Google Scholar]